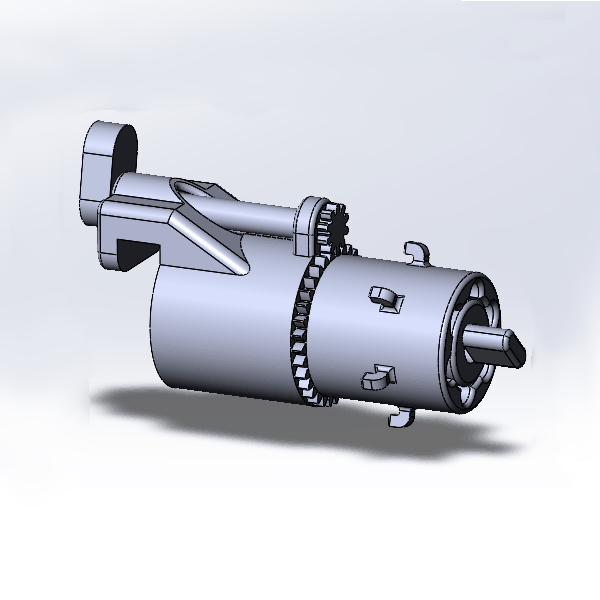

Class Project: 3D Printed Lock

Skills: [SolidWorks, Mechanical Design, 3D Printing, Rapid Prototyping]

This was the final group project for my Machine Design course. It was designed by a team of four and was based on a design I had developed earlier as part of an unfinished personal project. I was in charge of modeling and 3D printing the design, while other team members took the lead on calculating the spring and gear parameters and writing the report. While we each had a portion of the project we were primarily in charge of, there was also lots of collaboration between team members. We stuck to weekly meetings where we would all get caught up on everyone's progress and planned out the following week's work. This enabled us to stay on track and finish well before the deadline.

The design was based on a project I had initially started as a way to improve my SolidWorks and mechanical design skills. I wanted to design something that could be manufactured with only a 3D printer and readily available materials. I started my design with the pins because I didn't want to design other parts first and end up making the pins too small for 3D printing, which was a type of problem I had run into in the past on other projects. I chose the radial configuration of the pins as opposed to the typical vertical orientation because I knew the lock was going to be very big and I preferred that it stuck out away the drawer instead of extending upwards, blocking the drawers above. I modeled it up to the point of adding the gears and axle before moving on to other projects because I wasn't sure how to design the gear. After learning about gears in my Machine Design class, I decided to resurrect the project for the final group design project.

Our team designed both gears and springs for this project. The springs ended up being swapped out for rubber bands for

demonstration purposes because the springs were relatively expensive and couldn't be delivered in time. The prototype

was sized for a specific drawer, but the design could easily be modified and reprinted for others. Although this lock

is obviously far from impenetrable, the idea was to design a lock that could be cheaply produced and attached to a

container so that the user could see if the container had been accessed. This could be useful for something like first

aid supplies in an elementary school, which you would only want to give kids access to in an emergency, in which case

they would break the lock. The attachment point between the latch and the shaft was designed to be a stress concentration

so that the lock would fail at those easy-to-replace parts first.